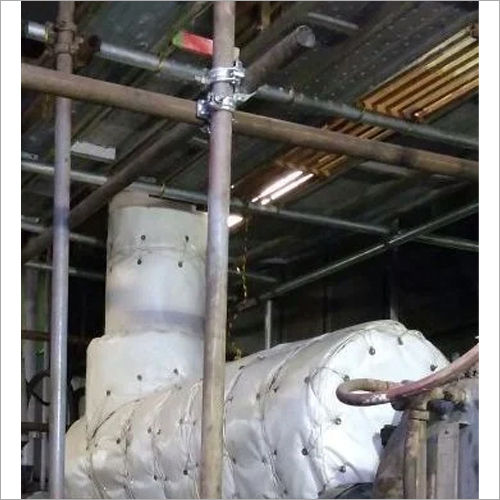

Removable and Reusable Insulation Jackets

Price 100 INR/ Piece

Removable and Reusable Insulation Jackets Specification

- Size

- Custom size as per equipment or pipe

- Surface Treatment

- Water and oil repellent treatment on external surface

- Thermal Conductivity

- 0.035-0.045 W/mK

- Layer

- Multi-layered construction (inner insulation, outer protective layer)

- Installation Guideline

- Wrap around the equipment and fasten with built-in straps or Velcro; detailed guidelines provided with each product

- Feature

- Removable, reusable, flexible, easy to install and remove

- Density

- 128 Gram per cubic centimeter(g/cm3)

- Coating Type

- Silicone or PTFE coated fiberglass fabric outer layer

- Product Type

- Removable and Reusable Insulation Jackets

- Material

- Lather

- Tensile Strength

- High tensile strength for repeated use

- Width

- Custom as per requirement

- Thickness

- 25mm to 150mm

- Application

- Thermal insulation for piping, valves, flanges, machinery and equipment in industrial plants

- Heat Conductivity

- Low thermal conductivity (0.035-0.045 W/mK)

- Color

- White

- Max Withstanding Temperature

- Up to 600C

- Environmental Resistance

- Resistant to oil, chemicals, and weathering

- Moisture Resistance

- Highly moisture resistant outer surface

- UV Resistance

- UV-stabilized outer layer for outdoor applications

- Shipping & Handling

- Supplied pre-fabricated, packed and labeled for project identification

- Fire Retardancy

- Meets ASTM E84 Class 1 flame spread requirements

- Custom Printing

- Company logo and safety markings available on request

- Corrosion Protection

- Minimizes under-insulation corrosion risk

- Maintenance

- Easy to clean and maintain while in service

- Inner Insulation Material

- Mineral wool or ceramic fiber as standard

- Fastening Options

- Velcro, stainless steel hooks, drawstrings, D-rings, or straps

- Reusable Cycles

- Engineered for over 200 installation-removal cycles

Removable and Reusable Insulation Jackets Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 - 3 Days

- Main Domestic Market

- All India

About Removable and Reusable Insulation Jackets

Superior Thermal and Environmental Protection

Our insulation jackets incorporate high-density mineral wool or ceramic fiber, offering exceptional heat retention while minimizing heat loss. The robust outer layer is engineered to resist moisture, oil, chemicals, and harsh weather, ensuring reliable performance in demanding environments. The jackets' UV-stabilized coating makes them suitable for both indoor and outdoor installations, effectively protecting critical infrastructure year-round.

Customizable and User-Friendly Installation

These insulation jackets are available in a range of sizes, thicknesses (25mm to 150mm), and widths to fit specific project needs. Installation is straightforward-simply wrap the jacket around the equipment and secure it with built-in straps, Velcro, hooks, D-rings, or drawstrings. Each unit includes detailed installation guidelines, and jackets are pre-fabricated and labeled for easy project identification and handling on-site.

FAQ's of Removable and Reusable Insulation Jackets:

Q: How are the removable insulation jackets installed and removed?

A: The insulation jackets are designed for quick and easy installation-just wrap them around the targeted pipes, machinery, or equipment and fasten using your preferred system (Velcro, hooks, drawstrings, D-rings, or straps). Removal follows the same process, making them fully reusable and convenient for maintenance or inspection.Q: What advantages do these jackets offer over traditional insulation methods?

A: They are reusable for over 200 cycles, simple to install and remove, and minimize downtime. Their multi-layered, highly durable design ensures consistent performance even in harsh industrial environments, while their custom fit, moisture, and UV resistance reduce risks of under-insulation corrosion and premature wear.Q: When should removable insulation jackets be used in an industrial facility?

A: Removable insulation jackets are ideal when frequent equipment access, inspection, or maintenance is needed. They are particularly useful on valves, flanges, and machinery where traditional, permanent insulation inhibits regular servicing.Q: Where can these insulation jackets be applied?

A: They are suitable for thermal insulation on a wide range of industrial equipment, including piping, valves, flanges, and machinery. Their environmental resistance makes them effective both indoors and outdoors across industries such as power generation, chemical processing, and manufacturing plants.Q: What are the key materials and features of these jackets?

A: The jackets feature a core of mineral wool or ceramic fiber for insulation, an outer layer of silicone or PTFE coated fiberglass for protection, and customizable fastening systems. They are resistant to moisture, oil, UV rays, chemicals, weather, and fire (meeting ASTM E84 Class 1 standards), while offering high tensile strength and low thermal conductivity.Q: How do these jackets benefit equipment maintenance and operations?

A: Their removable nature enables efficient access for routine inspections and repairs, reducing overall maintenance time and operational costs. The jackets' easy-to-clean surface means less downtime is required for upkeep, helping facilities maintain safety and energy efficiency.Q: Are custom sizes and branding options available?

A: Yes, jackets are made to match specific equipment sizes as per client requirements. Optional custom printing of company logos and safety markings can be provided upon request, supporting plant identification and compliance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Insulation Materials Category

Insulation Tape

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Insulation Tape

Coating Type : Pressure sensitive adhesive

Width : 18 mm

Application : Electrical insulation, wiring, cable bundling

Multi Layer Insulation For Cryogenic

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Multi Layer Insulation For Cryogenic

Coating Type : Aluminum Foil Coating

Width : 1.2 Meter

Application : Cryogenic Storage and Transfer Applications

Insulation Jacket For Engine Exhaust

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Insulation Jacket For Engine Exhaust And Engine Manifold

Coating Type : PTFE, silicone or aluminium foil reinforced

Width : Customized as per requirement

Application : Engine exhaust and manifold thermal insulation

Insulation Support Nails With Washers

Price 15.5 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Insulation Support Nails With Washers

Coating Type : Zinc coating

Width : Standard Washer Diameter: 30 mm

Application : Used for securing insulation boards to walls and ceilings

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry