Call: 07971191793

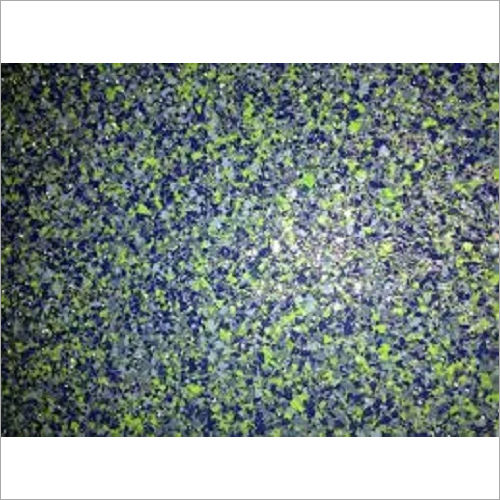

Epoxy And PU Flooring

Price 40 INR/ Square Meter

MOQ : 1 Piece

Epoxy And PU Flooring Specification

- Color

- Blue

- Wood Type

- Maple

- Type

- Plastic Flooring

- Material

- Spandex

- Metals Type

- Steel

- Plastic Type

- EVA

- Surface Treatment

- Polished Tiles

- Technics

- Three Layer Engineered Wood Flooring

Epoxy And PU Flooring Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 - 3 Days

- Main Domestic Market

- All India

About Epoxy And PU Flooring

Epoxy and PU flooring are two types of industrial floor coatings that provide a durable, long-lasting, and attractive finish for commercial and industrial flooring. It is made from a two-part resin system that is mixed together and then applied to the concrete substrate. The epoxy resin chemically bonds with the concrete surface to create a seamless, durable, and easy-to-clean floor. Epoxy and PU flooring is resistant to stains, chemicals, and abrasion, making it ideal for use in a wide range of industrial and commercial applications.

Exceptional Surface Finish

Epoxy and PU flooring utilizes advanced surface treatment, resulting in polished tiles that exude sophistication while delivering superior resistance to scratches and chemical exposure. This highly reflective finish enhances light distribution, underscoring both style and practicality for heavy-traffic areas.

Innovative Material Composition

With a combination of EVA plastic, spandex, and steel, this flooring system offers remarkable flexibility and strength. The inclusion of maple-inspired three-layer engineered wood creates a durable foundation, blending classic aesthetics with modern materials for lasting performance.

Trusted Supply Network

As one of India's prominent distributors, manufacturers, suppliers, and traders, we ensure consistent availability and compliance with quality standards. Our extensive expertise guarantees reliable delivery and after-sales support, facilitating seamless project execution for clients nationwide.

FAQ's of Epoxy And PU Flooring:

Q: How is the polished tile surface treatment achieved in Epoxy and PU flooring?

A: The polished tile surface is attained through a detailed finishing process, where flooring materials are treated to create a smooth, reflective texture. This technique not only improves appearance but also increases resistance to wear and prevents easy staining.Q: What materials are incorporated in this engineered wood and plastic flooring solution?

A: This flooring combines maple-style three-layer engineered wood with EVA plastic and spandex, further reinforced by steel components. The blend of these materials provides both flexibility and structural integrity, making it typical for commercial installations.Q: When is the ideal time to install Epoxy and PU flooring?

A: The best installation period is during dry weather to ensure proper curing of epoxy and PU compounds. Projects can be scheduled once existing subfloors are clean and moisture-free, optimizing adherence and durability.Q: Where can Epoxy and PU flooring be utilized effectively?

A: Epoxy and PU flooring is well suited to commercial complexes, industrial factories, educational facilities, healthcare centers, and retail outlets, thanks to its robust construction, easy maintenance, and attractive blue finish.Q: What are the primary steps involved in the flooring installation process?

A: The process comprises surface preparation, primer application, precise layering of engineered wood, placement of EVA and spandex, integration of steel for stability, and final coating to achieve a polished tile effect. Skilled personnel ensure seamless assembly and finishing.Q: How does this flooring enhance practical usage and benefit users?

A: Epoxy and PU flooring delivers high resistance to chemicals, abrasions, and moisture. Its resilient construction results in a longer product lifespan and reduced maintenance costs, while the aesthetic polished blue surface adds value to indoor environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Epoxy And Pu Flooring Category

Granite Finish Epoxy Flooring

Price 100 INR / Square Foot

Minimum Order Quantity : 1 Piece

Feature : Heat Insulation, EnvironmentallyFriendly, Other, Sound Absorption

Metals Type : Steel

Plastic Type : Acrylic

Material : Stone

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry