Call: 07971191793

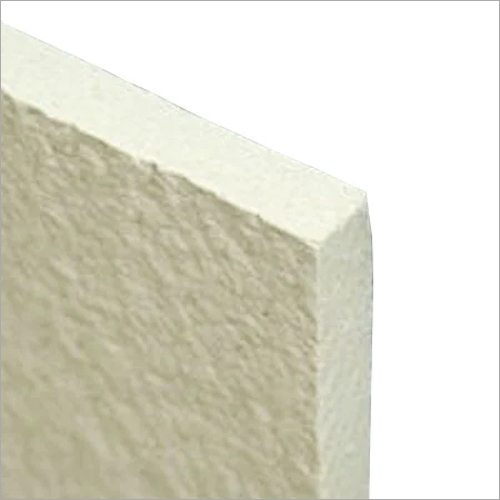

Calcium Silicate Boards

Price 55 INR/ Piece

MOQ : 1 Piece

Calcium Silicate Boards Specification

- Installation Guideline

- Can be cut, drilled, and fastened easily. Use standard screws and support frames.

- Thermal Conductivity

- 0.16 W/mK

- Size

- 1200 mm x 2400 mm

- Surface Treatment

- Smooth / Matte

- Coating Type

- Uncoated / primer available

- Feature

- Fire resistant, Moisture resistant, High strength

- Density

- 950 Gram per cubic centimeter(g/cm3)

- Layer

- Single / Multi layered

- Product Type

- Calcium Silicate Boards

- Material

- Mattel

- Rated Voltage

- N.A.

- Tensile Strength

- >8 MPa

- Width

- 1200 mm

- Thickness

- 6 mm, 8 mm, 10 mm, 12 mm, 15 mm, 20 mm

- Application

- Wall partition, False ceiling, Industrial insulation, Fire proofing

- Breakdown Voltage

- N.A.

- Heat Conductivity

- 0.16 W/mK

- Color

- BROWN

- Max Withstanding Temperature

- Up to 1100C

- Compressive Strength

- >16 MPa

- pH Value

- Neutral (7-8)

- Water Absorption

- <10%

- Edge Type

- Square, Tapered

- Fire Rating

- Class A

- Moisture Content

- <10%

- Flame Spread Index

- Zero

- Recyclability

- 100% recyclable

- Sound Insulation

- 35-40 dB

- Bending Strength

- >7 MPa

Calcium Silicate Boards Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 - 3 Days

- Main Domestic Market

- All India

About Calcium Silicate Boards

Calcium silicate boards are building materials composed of calcium silicate, a mineral compound made from a mixture of calcium oxide (lime) and silica (sand), along with fibers and other additives. The boards are known for their excellent thermal and fire-resistant properties, as well as their ability to withstand moisture and mold growth. Calcium silicate boards are commonly used in a variety of construction applications, including walls, ceilings, and floors, as well as for insulation and fire protection.

Exceptional Strength and Durability

These calcium silicate boards offer remarkable compressive (over 16 MPa) and tensile strength (over 8 MPa), making them suitable for both residential and industrial environments. Their robust nature ensures enduring performance, even under challenging conditions like high heat and humidity.

Superior Fire and Moisture Resistance

Class A fire rating and moisture resistance below 10% prevent flame spread and damage from damp environments. This makes the boards ideal for fireproofing and spaces requiring high protection against humidity, further securing structural integrity and occupant safety.

Versatile Applications and Easy Installation

Use these boards for wall partitioning, false ceilings, and insulation. The smooth/matte surface and varied thickness accommodate diverse design needs. Boards are easily cut, drilled, and set with standard screws onto regular support frames, streamlining the construction process.

FAQ's of Calcium Silicate Boards:

Q: How are calcium silicate boards installed for wall partition or ceiling applications?

A: Calcium silicate boards can be cut, drilled, and fastened with standard tools. Simply fix them to support frames using conventional screws. Their manageable size and square or tapered edges allow for straightforward installation in partition or ceiling systems.Q: What makes these boards ideal for fireproofing and industrial insulation?

A: With a Class A fire rating, flame spread index of zero, and maximum temperature resistance up to 1100C, these boards provide top-tier fire protection. Their excellent thermal conductivity and sound insulation also enhance industrial safety and comfort.Q: When should I use a primer or coating on these boards?

A: The boards come uncoated but primer options are available if further surface protection or painting is desired. Using a primer is recommended in areas with high moisture exposure or where a finished surface is required.Q: Where can calcium silicate boards be utilized effectively?

A: They are designed for wall partitions, false ceilings, industrial insulation, and fireproofing. Common installations include commercial or residential buildings and factories where fire safety, sound insulation, and moisture resistance are important.Q: What benefits does the recyclability feature provide?

A: Being 100% recyclable, these boards support environmentally conscious projects and help reduce waste. At the end of their lifecycle, they can be processed and reused in new materials rather than ending up in landfills.Q: How does the board's density and strength contribute to performance?

A: With a density of 950 g/cm3 and high bending, tensile, and compressive strengths, the boards maintain structural integrity under load and resist damage from impacts, making them dependable in demanding conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Backup Insulation Category

Microporous Silica Boards

Price 6500 INR / Piece

Minimum Order Quantity : 1 Piece

Layer : Single or multilayer as required

Density : 330 Gram per cubic centimeter(g/cm3)

Material : Marble

Coating Type : Uncoated or with customized coatings

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry